|

Type |

Input power max. |

Input rpm |

Propeller rpm max. |

Max. Dia. |

Weight[Kg] |

|||

|

KW |

HP |

No nozzle |

With nozzle |

No nozzle |

No nozzle |

|||

|

SZP 5A |

50 |

68 |

2400 / 2200 / 2000 / 1800 |

1350 |

450 |

420 |

65 |

|

|

SZP 5B |

1500 / 1200 / 1000 |

78 |

||||||

|

SZP 8A |

80 |

109 |

2200 / 2000 / 1800 / 1600 |

1055 |

580 |

550 |

115 |

|

|

SZP 8B |

1500 / 1200 / 1000 / 900 |

138 |

||||||

|

SZP 10A |

100 |

136 |

2200 / 2000 / 1800 / 1600 |

926 |

660 |

630 |

190 |

|

|

SZP 10B |

1500 / 1200 / 1000 / 900 |

228 |

||||||

|

SZP 15A |

150 |

204 |

2200 / 2000 / 1800 / 1600 |

764 |

836 |

800 |

770 |

280 |

|

SZP 15B |

1500 / 1200 / 1000 / 900 |

336 |

||||||

|

SZP 20A |

200 |

272 |

2000 / 1800 / 1600 / 1500 |

644 |

728 |

920 |

880 |

365 |

|

SZP 20B |

1200 / 1000 / 900 / 800 |

438 |

||||||

|

SZP 25A |

250 |

340 |

2000 / 1800 / 1600 / 1500 |

582 |

640 |

1050 |

1000 |

1170 |

|

SZP 25B |

1200 / 1000 / 900 / 800 |

1405 |

||||||

|

SZP 30A |

300 |

408 |

2000 / 1800 / 1600 / 1500 |

531 |

556 |

1150 |

1100 |

1370 |

|

SZP 30B |

1200 / 1000 / 900 / 800 |

1645 |

||||||

|

SZP 35A |

350 |

476 |

2000 / 1800 / 1600 / 1500 |

477 |

522.5 |

1230 |

1175 |

1735 |

|

SZP 35B |

1200 / 1000 / 900 / 800 |

2082 |

||||||

|

SZP 40A |

400 |

544 |

1800 / 1500 / 1200 |

463 |

489 |

1320 |

1250 |

2100 |

|

SZP 40B |

1000 / 900 / 825 / 750 / 600 |

2520 |

||||||

|

SZP 50A |

500 |

680 |

1800 / 1500 / 1200 |

413 |

436 |

1480 |

1400 |

2500 |

|

SZP 50B |

1000 / 900 / 825 / 750 / 600 |

2750 |

||||||

|

SZP 60A |

600 |

816 |

1800 / 1600 / 1500 / 1200 |

377 |

407 |

1620 |

1500 |

2800 |

|

SZP 60B |

1000 / 900 / 825 / 750 / 600 |

3080 |

||||||

|

SZP 75A |

750 |

1020 |

1800 / 1600 / 1500 / 1200 |

339 |

408.6 |

1800 |

1680 |

4500 |

|

SZP 75B |

1000 / 900 / 825 / 750 / 600 |

4950 |

||||||

|

SZP 90A |

900 |

1224 |

1800 / 1600 / 1500 / 1200 |

306 |

380 |

2000 |

1800 |

6000 |

|

SZP 90B |

1000 / 900 / 825 / 750 / 600 |

6600 |

||||||

|

SZP 110A |

1105 |

1503 |

1800 / 1600 / 1500 / 1200 |

278 |

360 |

2200 |

2000 |

7000 |

|

SZP 110B |

1000 / 900 / 825 / 750 / 600 |

7700 |

||||||

|

SZP 130A |

1325 |

1802 |

1800 / 1600 / 1500 / 1200 |

255 |

307 |

2400 |

2150 |

18000 |

|

SZP 130B |

1000 / 900 / 825 / 750 / 600 |

|||||||

|

SZP 150A |

1500 |

2040 |

1800 / 1600 / 1500 / 1200 |

240 |

278 |

2550 |

2300 |

20000 |

|

SZP 150B |

1000 / 900 / 825 / 750 / 600 |

|||||||

|

SZP 170A |

1765 |

2400 |

1600 / 1500 / 1200 / 1000 |

222 |

256 |

2750 |

2500 |

22000 |

|

SZP 170B |

900 / 825 / 750 / 550 |

|||||||

|

SZP 190A |

1912 |

2600 |

1600 / 1500 / 1200 / 1000 |

210 |

246 |

2900 |

2600 |

24000 |

|

SZP 190B |

900 / 825 / 750 / 550 |

|||||||

|

SZP 220A |

2206 |

3000 |

1600 / 1500 / 1200 / 1000 |

196 |

226 |

3100 |

2800 |

28000 |

|

SZP 220B |

900 / 825 / 750 / 550 |

|||||||

|

SZP 260A |

2600 |

3536 |

1600 / 1500 / 1200 / 1000 |

180 |

213 |

3400 |

3000 |

41000 |

|

SZP 260B |

900 / 825 / 750 / 550 |

|||||||

|

SZP 300A |

3000 |

4080 |

1600 / 1500 / 1200 / 1000 |

168 |

198 |

3650 |

3250 |

53000 |

|

SZP 300B |

900 / 825 / 750 / 550 |

|||||||

Product Categories

- Cummins Engine (354)

- Cummins Generator Set (94)

- Cummins Power Unit (11)

- Power Unit (3)

- Pump Unit (3)

- Marine Power Unit (5)

- Marine Equipment (100)

- Marine Deck Machinery (13)

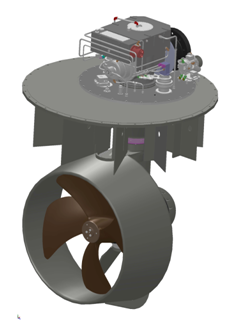

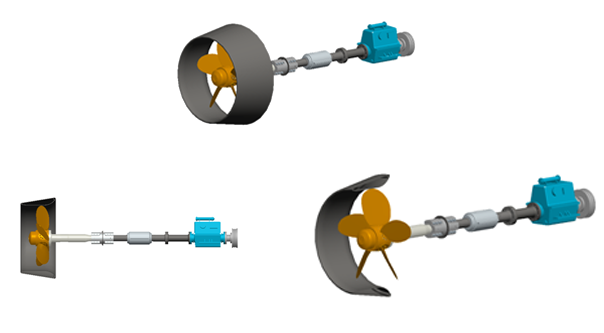

- Propulsion System (3)

- Marine Electrical System (2)

- Advance GearBox (82)

- Cummins Spare Parts (640)

- Cummins Parts Catalogue (95)

- Cummins Engine Parts (541)

- Control System (4)